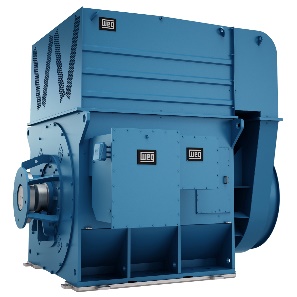

Technical Characteristics:

|

Output |

: |

up to 150.000 kW |

|

Speeds |

: |

3.600 up to 150 rpm |

|

Frame |

: |

132 up to 450 |

|

Voltage |

: |

up to 13.800 V |

|

Frequency |

: |

50 or 60 Hz |

|

Enclosure |

: |

IC01 (IP23 to IP24), IC611 (IP54 to IP65), IC81W (IP54 to IP65) |

|

Insulation Class |

: |

F |

|

Temperature Rise |

: |

B (80K) |

|

Ambient Temperature |

: |

-20˚ C to +40˚ C at 1000m.a.s.l. |

|

Frame Material |

: |

Cast iron or Welded steel |

|

Thermal Protection |

: |

RTD PT100 two per phase and one per bearing |

|

Construction |

: |

Horizontal / Vertical |

|

Standard |

: |

IEC / NEMA |

|

Manufacturing Site |

: |

WEG Motors (Brazil) |

|

Types of Excitation: |

|

Synchronous motors require a source of direct current in order to supply the necessary power to the fields winding (rotor winding), which is usually provided by a rotating brushless exciter or by slip rings and brushes (static exciter). |

|

Static exciter (with brushes): |

|

Synchronous motors with static exciter are designed with slip rings and brushes that allow the current supply to reach the rotor poles by means of sliding contact. The direct current must come from an AC/DC static controller and converter located outside the motor. Synchronous motors with static exciter are more often used in application with variable speed with a frequency drive operation or in applications where the system dynamic response must be extremely fast. |

|

Synchronous motors with brushless excitation system present a rotating exciter, normally located in a compartment in the back of the motor. Depending on the motor operation, the exciter is composed by: Exciter with direct current supply on the stator Exciter with alternating current supply on the stator The exciter rotor supplies the necessary power to the motor excitation winding through a rotating, three-phase rectifier brigde. |